Excavators, with their distinctive boom, dipper stick, and bucket, are indispensable pieces of heavy machinery found on construction sites, mining operations, and various other industrial settings. Their versatility stems from their ability to perform a wide range of tasks, making them a crucial asset in numerous projects. This article delves into the diverse applications of excavators, exploring their capabilities and the industries they serve.

Understanding the Excavator's Core Functionality

At its core, an excavator is designed for digging and moving earth. However, its capabilities extend far beyond simple excavation. The hydraulic system, which powers the boom, dipper stick, and bucket, allows for precise control and significant lifting power. The rotating cab enables the operator to work in a 360-degree radius, enhancing efficiency and maneuverability.

Common Applications in Construction

Construction is perhaps the most prevalent sector where excavators are employed. Some of the common applications include:

Foundation Excavation: Excavators are used to dig trenches and foundations for buildings, bridges, and other structures. They ensure precise depth and dimensions, crucial for structural integrity.

Site Preparation: Before construction begins, excavators clear land, remove debris, and level the ground. This prepares the site for further development.

Trenching and Pipe Laying: Excavators dig trenches for utility lines, such as water pipes, sewage systems, and electrical cables. Their precision minimizes damage to existing infrastructure.

Road Construction: Excavators are used to grade roads, dig drainage ditches, and move materials during road construction and maintenance.

Demolition: Equipped with specialized attachments, excavators demolish buildings, bridges, and other structures. Their power and maneuverability make them ideal for controlled demolition.

Material Handling: Excavators move and load materials, such as soil, gravel, and debris, onto trucks or other transport vehicles.

Mining and Quarrying Operations

Excavators play a vital role in mining and quarrying, where large volumes of earth and rock need to be moved.

Ore Extraction: In open-pit mines, excavators extract ore and other valuable minerals from the earth.

Overburden Removal: Excavators remove overburden, the layer of soil and rock covering the ore deposit, to access the desired minerals.

Quarry Operations: In quarries, excavators extract stone, gravel, and other aggregates for construction and industrial use.

Mine Site Reclamation: After mining operations cease, excavators are used to reclaim the land, restoring it to a usable state.

Landscaping and Forestry Applications

Beyond construction and mining, excavators find applications in landscaping and forestry.

Landscaping: Excavators are used to create ponds, terraces, and other landscape features. They also move trees and large rocks for landscaping projects.

Forestry: In forestry, excavators are used for logging, clearing brush, and building access roads. They help manage forests and reduce fire hazards.

Disaster Relief: After natural disasters, excavators clear debris, remove fallen trees, and assist in rescue operations.

Specialized Attachments and Their Functions

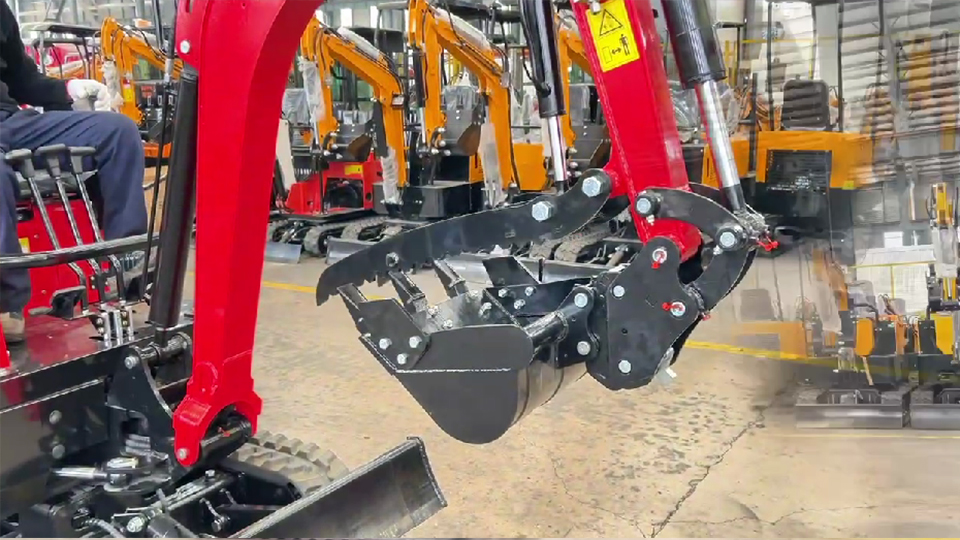

The versatility of excavators is further enhanced by the availability of various attachments, each designed for specific tasks:

Hydraulic Breakers: These attachments break up concrete, rock, and other hard materials.

Grapples: Grapples are used to grab and move logs, debris, and other bulky materials.

Augers: Augers drill holes for fence posts, utility poles, and other applications.

Compactors: Compactors compact soil and other materials for road construction and site preparation.

Shears: Shears cut through metal and other materials during demolition and recycling operations.

Rippers: Rippers loosen hard soil and rock, making it easier to excavate.

Mulchers: Mulchers turn trees and brush into mulch, reducing debris and fire hazards.

Technological Advancements in Excavator Technology

Modern excavators incorporate advanced technologies that enhance their performance and efficiency:

GPS and Machine Control: GPS and machine control systems provide precise positioning and grading, reducing the need for manual surveying.

Telematics: Telematics systems monitor machine performance, track fuel consumption, and provide maintenance alerts.

Hybrid and Electric Models: Hybrid and electric excavators reduce fuel consumption and emissions, contributing to a more sustainable environment.

Advanced Hydraulic Systems: Advanced hydraulic systems provide greater power and precision, improving overall performance.

Safety Features: Modern excavators include advanced safety features, such as rollover protection systems (ROPS) and falling object protective structures (FOPS).

Maintenance and Operation Considerations

Proper maintenance and operation are crucial for ensuring the longevity and safety of excavators.

Regular Inspections: Conduct regular inspections of the hydraulic system, engine, and other components.

Scheduled Maintenance: Follow the manufacturer's recommended maintenance schedule.

Operator Training: Ensure operators are properly trained and certified to operate excavators safely and efficiently.

Safety Protocols: Adhere to safety protocols, such as wearing appropriate personal protective equipment (PPE) and following safe operating procedures.

Conclusion

Excavators are versatile and powerful machines that play a crucial role in various industries. Their ability to perform a wide range of tasks, from excavation and material handling to demolition and landscaping, makes them indispensable on construction sites, mining operations, and other industrial settings. As technology advances, excavators continue to evolve, becoming more efficient, precise, and environmentally friendly.

Post time:Sep-25-2020